|

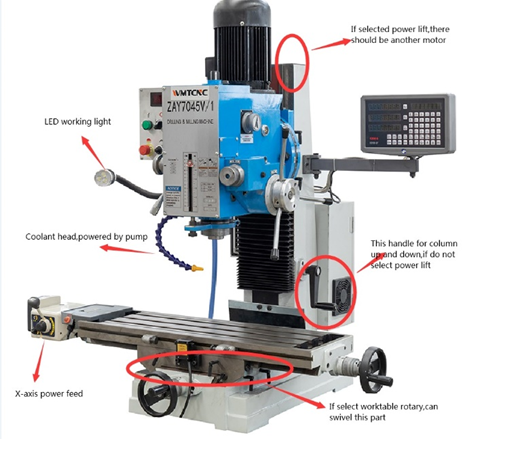

Seven Additional Problems With WMT Machine |

In addition to the main issue of no R8 spindle and wild wobbling, the ZAY7045V/1 quill locking mechanism is defective and will not allow accurate setting of depths of cut because the vertical

movement is "jerky."

The machicne also had the following seven problems when it was delivered.

- Delivered without toolbox and the two hand cranks for the milling machine table. Kind of like delivering a car without the steering wheel.

- Depth gage could not be set to zero, shipped with low battery. That should have been verified before shipping.

- Speed display failed with bare minimum usage, see the Speed Display Video

- Panel mounting nut for the emergency stop was improperly installed causing the entire switch assembly to fall back into the rat's nest of control panel wiring.

- The machine appears to have been bumped or dropped, a few spots in the casting have been filled with some kind of Bondo and brush painting

- Besides the issue of spindle run-out the entire quill assembly is excessively tight and difficult to move up or down even with the quill lock completely backed off.

This makes it impossible to accurately set a depth of cut.

- No instructions were provided for the DRO, had to make a special request for them from WMT.